Cubflyer

-

Posts

337 -

Joined

-

Last visited

Content Type

Forums

Downloads

Articles

Gallery

Blogs

Events

Store

Posts posted by Cubflyer

-

-

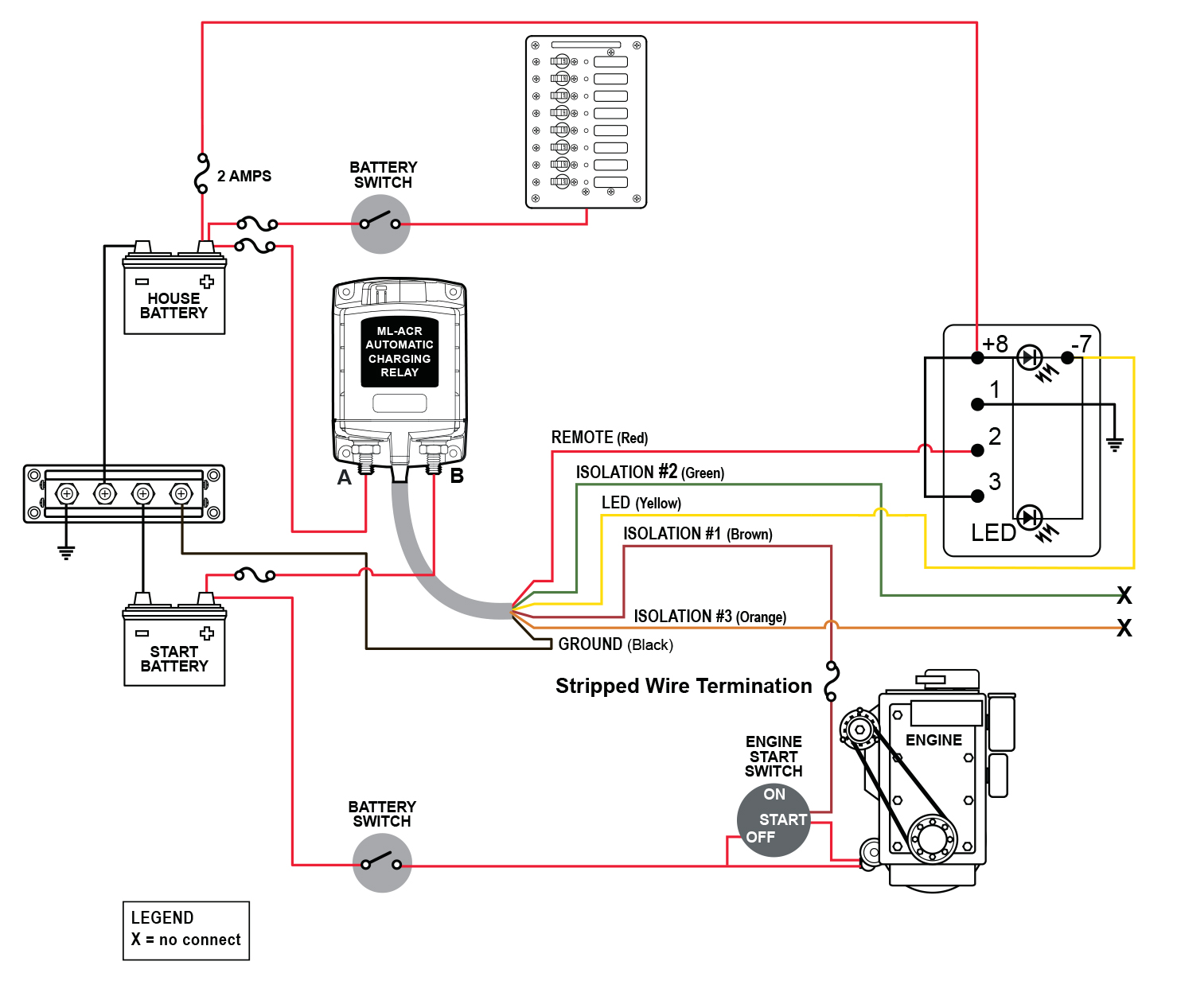

The stated purpose of the ML ACR is: 'An automatic charge relay (ACR) performs several tasks. It combines two battery banks to charge them from a single source' The original "BigBOY" relay it replaced, just combined the two banks of batteries for starting.

....Single source of charging,....... the engine alternator output is connected to the chassis battery at the ACR, the house charger (inverter) is connected to the house batteries at the A+ and Negative of the house batteries, therefore when the inverter is a 'source', powered by either shore power or the genny, and you are running the engine there are two charging sources. As for the third (solar) charging source (in my MH connected directly to the house batteries) it is not a very large output, just a few amps verses an engine driven alternator or an inverter.... so it does not seem to interfere with the engine alternator when the house and chassis batteries are combined.

FWIW....I did not connect the brown isolation wire up, so maybe that would isolate the two batteries when running the engine and it would (automatically) be isolating the house and chassis batteries when the ignition switch was on (engine running)......... Ken

-

-

You have a Queen that will drive that coach?? Much less one that will drive it alone!! Wow is all I can say….

As for the ML ACR, my switch stays in Auto, unless operating the engine with an operational alternator AND the Genny with an operational generator …. And in that case, I isolate the two sources of power, by selecting OFF. It is bad practice to provide more than one source of charging power to the ML ACR…. I did that once and got an ALT (fail) light on my dash…. Only time I would lock it ON would be if I needed house batteries to start/boost chassis batteriesKen

-

1

1

-

-

On 9/6/2022 at 5:30 PM, Tom Cherry said:

Added Watts. Could have easily driven one hand or a few fingers.

my same experience, the Watts link on the front, crossbars on the back, HUGE improvement... IMHO, TRW steering box not needed... precise steering not required if the coach is stable on it's own.

-

Download it, save as a PDF, go to an 'office store" and have them print the file...

-

Looks like it may be a good item to add to a recurrent inspection list. Check for cracks, loose bolts, solid welds, etc. I do not believe that sheared off, completely, all the way around without being cracked partially, for awhile, before this incident.

-

1

1

-

-

1 hour ago, Rikadoo said:

turn off the electric heater an see what happens. Now the EMS read out changes from 14 to 7 amps and almost instantly my battery voltage starts climbing,

It sounds to me like you were running the electric heater on an inverter outlet.... and as far as I know... (correct me if I'm wrong...) I do not believe your inverter can not output AC power to the outlets and charge the batteries at the same time.... (unless on shore power (30 or higher amp)).

OR... the inverter 'load sheds' battery charging when it has "limited" AC amperage input.....

Ken

-

working good here! Thanks for all you do!

-

3 minutes ago, Ivan K said:

I had to jumper both banks together with a piece of wire i had available. You would likely have a different factory system so just make sure both banks get charged by the generator, be it through the big boy or a jumper.

As Ivan said, you need to be sure that both house and chassis batteries are being charged by the genny.... I have a BlueSea in place of my Big boy contactor (that joins the two battery banks together). That allows me to run them isolated or automatically charging the lowest battery or combined (to do just what you are needing at this time). I never run combined when driving with both the alternator and genny charging... (two sources of charge fighting to charge one combined set of batteries... bad)

Ken

-

Tom,

That is great news! Looking back, do you think the first (original) problem was the ECM? Lesson from this being... Computer diagnostic is critical once you are sure all the basics (fuel-air-spark(compression)) are there? I'm knocking on wood hoping I never have to go thru what you just did! Glad you made it.

Ken

-

11 hours ago, TomV48 said:

Tempted to add the cross links to the front too, but, thinking I need to be rid of the Sheppard M100 steering gear in favor of a TRW box first.

Tom,

If you already have the watts link up front, the cross links/bars are redundant... watts links are actually better at holding things steady.... One of the big reasons that cross links are not used in the front, and more expensive watts links is because of the genny up front does not let the cross links fit.

Rik,

I installed the front watts link and the rear cross link rods, I would do that (one day job for both if you want to work all day) I prefer to work a couple of hours a day these days... The challenge these days is (or can be) availability of the watts link and cross link rod kits. Might have to wait to get them.

I'm not sure on the "slide out support", ..... what slide are you referring to? I installed the plates on my bedroom slideout, easy job, takes a few hours.

Both were a couple of the best things I did.... One man job for the most part, but extra hands can be helpful if nothing more than saving you from crawling in and out from underneath the coach

Ken

-

Sorry to hear this is giving you such a rough time.... please keep us updated... You are into things way past my 'paygrade/knowledge/experience'... Ken

-

Tom,

Are you up and running again??

Ken

-

58 minutes ago, thancoc@bellsouth.net said:

Am I missing anything?

I'm no expert. I do not know what or if any codes will be displayed by a capps failure... BUT I sure wanted you to be SURE the CAPPS pump had a good fuel supply before condemning the CAPP$$ pump. Sounds like you did, but again, I was amazed at how much time with constant air pressure on my tank, with a fulltime running FASS pump while cranking the engine it took for it to fire up..... and that was after bleeding the fuel line I had replaced!

Ken

-

Last fall on my way to Pensacola, FL coming thru Mobile, AL I discovered that my fuel line between my FASS pump and the filter on the engine just before the CAPPS injector pump had a pin hole. I turned off the FASS pump, and continued to Pensacola. The MH sat there for a couple of months, I bought a new fuel hose and installed it.

I tried to start the engine, after running the FASS pump thinking that it would have no problem filling that new fuel hose..... I was wrong, engine just sputtered, and gray smoke.... (FASS pumps put out lots of volume, and 18-20 psi).

So then I put air pressure on the fuel tank, ran the FASS pump and cracked the fuel line I had replaced at the engine end until fuel flowed out if it. Cranked it again with air on the tank and the FASS pump running and the engine finally fired and has run like a top ever since.

My point here is, it takes an amazing amount of "bleeding" to get the air out of the system... you said you replaced filters (first thing), then found the lift pump gasket leaking.... I'm telling you, do not replace that CAPPS pump until you are SURE that it is getting a solid supply of fuel... no air.

Diesels run on fuel.... fuel starved engines do not run.... I'm betting a fuel starved CAPPS put out fault codes .....

It's not expensive, it's not hard to do.... blow and bleed the crXp out of that thing before you spend 6-7-8k on a CAPPS pump!

Ken

-

8 hours ago, Ivan K said:

Here is an extreme case when sliders get stuck and left unattended.

What a great photo Ivan! Showing one side of a disk brake rotor totally shot while the other side looks new!

-

On 10/26/2022 at 5:56 PM, thancoc@bellsouth.net said:

Up on further review my lift pump is leaking.

This problem started with a -no start-, the first thing you did was replace the fuel filters, (inducing a bunch of air into the fuel supply system), then you had a fuel leak at the lift pump, still no start, now you are going to change a lift pump gasket and hope it starts....

What is your game plan if 1- you can not change the gasket (wrong gasket or since that gasket change is a bit of a PITA) 2- you get the gasket changed and still no start?

If it were me, I would concentrate on getting the engine running (seems fuel to the injector pump IS the problem), by forcing fuel through those new filters and to the lift pump and on the the injector pump...... many an engine would not start after fuel filter changes as pumps can not pump air very well, you need to prime the pumps!

Once running, determine if the lift pump is leaking a little or a lot. I drove mine (unknowingly) from south FL to Memphis, where I realized that the drip of liquid (fuel) hanging off the starter was a sign of a leaking lift pump.

Best of luck,

Ken

-

29 minutes ago, Tim-AZ said:

......... didn't have a leak on my lift pump. Just a thought to make the FASS more of a priority. I bought my coach in 2017 so I have no idea if there was a leak before.

When I first got my coach, it had a leaking gasket at the lift pump...... BUT, I did not know it.... I only discovered it when I was t/s a ABS light problem. I was turning the key on and off a number of times without starting the engine..... pretty soon I noticed a puddle of fuel under the engine, dripping from the starter... I 'lucked out' and promptly bypassed that pump and installed a FASS system. Best thing I ever did for my engine, and gained the knowledge that the injector pump always has a positive pressure of clean air-free fuel to it's inlet (from the FASS) with a fuel pressure gauge installation.

Ken

-

2 hours ago, Hypoxia said:

It's been a while since I changed an ISC lift pump. I thought the lift pump fed directly into the injector pump and all filtering was prior to the lift pump.

Jim C

It would appear that your photos are of an ISX lift pump since it does not look like the ISC pump on my 2003 8.3. I am sure that on my 2003 8.3 ISC engine the output of the factory, engine mounted lift pump feeds directly (through a rigid metal tube) to a spin-on filter before continuing on to the injector pump.

The mounting bolts (three) are long and install from the top down through the housing body and screw into the lift pump... From your photos the ISX lift pump seems to mount differently...

Ken

-

3 minutes ago, thancoc@bellsouth.net said:

is there a cap I can buy for the fuel tank pressure? Will a rag do the trick?

You might try blowing air into the tank by way of the vent also, not sure if that will work due to the rollover check valve, but it should... try there first, then if not a rag wrapped tight should work. I believe the fuel cap is just a 2" (or so) pipe thread, so you could get a plumbing cap (rubber?) and put a small hole in it.... be careful to not put too much pressure on the tank... it should only need a couple of psi....

Ken

-

Those three bolts I believe are metric..... 6mm or 8mm... I'm old and tightened mine almost two years ago.... I'm not sure of the size, but 1/4" drive 18" extension with swivel socket or u-joint will help.

If your lift pump is running, but no fuel is being pumped, it most likely lost it's prime, the gasket that leaks and drips down on the starter usually leaks with lift pump ops and no engine start (like when you just cycle the ignition key but do not engage the starter, that's how I found out mine was leaking). That gasket leaking allows the injector pump to draw air when the engine is running and the (30 sec) lift pump is not running.

Sounds like you need to put that air pressure on the fuel tank to force fuel to the lift pump.... to get the engine to start/run. Get it running and find out why it lost it's prime later...

-

Once you tighten the three bolts, loosen the filter just down stream of the lift pump, before the injector pump. Get a rag, wrap it around an air nozzle, and blow air into the filler neck of your fuel tank, watch for fuel to leak from the loose filter, tighten that filter and keeping the air pressure on the tank, start the engine....

-

18 minutes ago, DavidL said:

How many gallons go in the tank (use the fuel stations measurement) divided by how many miles traveled. Since it's very hard to consistently get the tank to the same degree of "fullness", there is always some inconsistencies

Rik,

I have found, that the side to side angle of the coach at the fueling station has a larger effect on MPG than hills or things being towed... I've seen swings like yours running flat lands and the same speeds. I do a mileage-fuel pumped calculation every fill up and have never gotten two the same in a row... same day, same terrain.

But I LOVED your story!!

Ken

46 minutes ago, Rikadoo said:MPG is such a elusive beast

-

1 hour ago, tmw188 said:

There was something too about you shouldn’t use a fitting off the return side of the pump but use just the fuel line supplied in a sweeping 90?

Todd, What you may be referring to is FASS do not want a 90 degree fitting right off of the FASS assembly, but the photo you linked with a 90 degree sweep fitting should be fine (good) (not a problem).. 90 degree elbow fittings are restrictive of flow, 90 degree sweeps are not (so much, hardly at all) restrictive.

Also, the 90 degree sweep fitting in the photo coming off the FASS system seems to be steel with a nickel or cad plating, not zinc... Only the fittings at the fuel tank photo are zinc. I kind of believe the zinc is not a major issue, being in the 'flow' verses being the 'container'..... mostly due to time of exposure...

Ken

ML ACR

in Batteries

Posted

I'm not sure what the brown wire does/interacts with the ACR either. My ACR works for me as advertised without the brown wire connected.

My ALT light did not come on immediately, it took a while on the road for it to start 'glowing' faintly, I uncoupled the battery banks with my remote switch, allowing them to charge/operate separately and the light went out... Again, having all the batteries connected together and having the engine alternator and the inverter 'charging' them, just did not play well, I sure did not want to chance hurting my alternator or my inverter, and I viewed the ALT fail light as fair warning.... others experiences may vary.....

Ken